21 February 1904 - 7 April 1980

Elected F.R.S. 1940

BY F. D. RICHARDSON, F.R.S.

Main Page

CHARLES FREDERICK GOODEVE was born on 21 February 1904 in the small town of Neepawa. This stood on the eastern edge of the prairies one hundred miles west of Winnipeg. When he was three the family moved to Stonewall some twenty miles north of Winnipeg. In those days such distances were substantial journeys especially in winter and spring, even if one were the lucky owner of a Ford. But Charles's father, F. W. Goodeve, M.A., was an Anglican clergyman with means that did not run to a family car. So Charles's early years were small town years but there were compensations: he was one of a family of five, with two older sisters and two younger brothers. His mother, Emma (née Hand), was a woman of skill and energy, who determined to do the very best for her children despite her husband's slender income.

Both Emma and her husband were first generation Canadians. On the Goodeve side, Charles's grandfather, Charles Frederick, had been born in London in 1830 and was taken with his family to Canada in 1832. His great-grandfather, William Daniel Goodeve, had been the brewer in Wimborne, Dorset, before he emigrated. William Daniel appears to have been the only technologist among Charles's forbears.

When Charles was ten his father moved to a church in Winnipeg, so life and schooling became more sophisticated. The family bought a cabin at Gull Harbour on Lake Winnipeg and there spent some months each summer enjoying the wilds and gathering and bottling all the fruit and berries they could to stock their winter larder. Charles and one of his brothers got hold of an old boat which they refurbished and sailed on the lake. That was how he developed his love of boats which later led to his naval career. In 1924 Charles's father became Rector of St Philip's Church in Norwood, a suburb of Winnipeg, and while there became a Canon of St John's Cathedral.

In Winnipeg Charles went to the Kelvin High School, where Mr Wilson the science teacher aroused his scientific interests. His mother regarded Charles as the cleverest of her children and was determined he should go to university, although he initially tried his hand at accountancy. However, he greatly disliked balancing books to a degree of accuracy that he considered unjustifiable, and in 1919 he entered Manitoba University as an arts student. He transferred to science two years later and in 1925 passed his B.Sc. exams with honours in chemistry and physics. At that time there were only about 25 students in the whole four years of the pure science faculty. The staff-student ratio was high, for in chemistry alone there were three senior staff including the head of department, and two senior demonstrators. So instruction was on an almost personal basis.

Charles's course in chemistry required physics in all four years but mathematics was not mandatory. So he never took formal instruction in mathematics—but his fellow students found him very capable at mathematics and he made skilful use of available texts whenever a problem required a mathematical solution.

During his early years at university, Charles was hard pressed for money, so he made all he could by working on the side: cutting grass and cleaning windows in the summer, installing double glazing against the prairie winter in the autumn and removing it in the spring. In his second year he secured an appointment as a junior laboratory demonstrator and this paid his tuition fees. This appointment naturally gave him access to chemicals and it is said he talked his barber into giving him free haircuts in return for a specially designed hair lotion!

Towards the end of Charles's degree course there was an explosion in a domestic boiler heated electrically in Winnipeg. This was serious because the cause was not understood and the majority of Winnipeg residents relied upon this method of obtaining their hot water. The problem was referred to the Professor of Physical Chemistry and came immediately to Charles's notice because of the close association between students and staff. When it appeared that the investigation was proving rather unsuccessful, Charles cautiously asked for details. He found that the current (11OV a.c.) instead of passing through wire-wound heating elements, went directly through the water between iron electrodes. It was assumed there was no electrolysis, but J. W. Shipley, an assistant professor in the department working with A. Blackie, soon showed that explosive mixture of gases was slowly produced by the a.c.

Now some years before this an engineering student, who was a lodger in the Goodeve household, had shown Charles how to electrolyse water by breaking the tip of a burnt-out vacuum-light bulb under water (so that the water rushed in) and then inserting the bulb in a lamp socket. An explosive mixture of gases was slowly produced within it. Charles thus realized that the explosive gases in the hot water cylinders were produced by electrolysis and he went on to design experiments in collaboration with Shipley. These showed that with electrodes made from platinum, iron, copper, silver, nickel or carbon the water was electrolysed into hydrogen and oxygen provided the current densities were sufficiently high (greater than 0.2 A/cm2) . The influence of temperature on the rate of generation of these gases was established. More importantly it was shown that currents over and above a critical density gave amounts of gas approximately consistent with Faraday's Laws, provided the critical current was subtracted from the actual current. The mechanism was as follows: during a cycle there would be a short evolution of hydrogen which ceased on reversal of the current; oxygen was then discharged at the electrode and adsorbed until the surface was saturated; further oxygen, was then evolved until the next reversal of current; the hydrogen then produced first reduced the absorbed oxygen and after that was evolved as gas, the whole process continuing with each cycle. Together with Shipley, Charles also showed how this critical current could be reached in boilers supposedly working at much lower current densities, by reason of poor design of the electrodes or to their corrosion in use. The research, which was mostly conducted after Charles's graduation, was very successful and the results were published in 1927 and 1928.

Although Charles passed his B.Sc. exams in 1925, he was not granted his degree until the French language exam (which he had failed) ceased to be a requirement. For the next two years he held an assistant lectureship and continued to work on his electrolytic problem. He obtained an M. Sc. in Electrochemistry in 1927 and in that same year was awarded an 1851 Exhibition Scholarship to be held at University College London. In 1928 he was given the Scientific Club of Manitoba Prize and the Plummer Gold Medal of the Engineering Society of Canada, both for his electrolytic researches.

During his third year at University, Charles's sailing interests led him to join the Royal Canadian Naval Volunteer Reserve. This had just been formed and the bait for enlistment was a two-week training period at the coast each year. The idea caught on at once and very soon there were R.C.N.V.R. companies in the main prairie towns. Drill was required one evening a week and before long it was not unusual to see a naval church parade as far from the sea as it was possible to get. Officers were encouraged to train as long as they possibly could. The pay was attractive and more than covered expenses. Charles enlisted as a midshipman; he took every opportunity to go to sea, and so escaped the geographical confines of Winnipeg. His social poise developed rapidly and by the time he left for England he could handle himself in any situation.

Before leaving Canada, Charles had one naval goal that he desperately wanted to attain. As Gerald Pawle wrote in The secret war:

'He had long been waiting for a chance to take his final Navigation test, and a few weeks before sailing for England he was ordered to report at Esquimalt. He was to take the ancient destroyer Patrician to sea, carry out certain manoeuvres and anchor her in the Bay. After sleepless nights, going through every detail of procedure and word of command, the great day had come. The Patrician had been undergoing major repairs to her engines, a not infrequent occurrence, but when Goodeve went on board and asked anxiously whether she would be ready for sea he was told that all was well. 'They've patched her up again. You're to take her out of harbour at 0900', said the Captain to the nervous candidate.'At 0857 Charles gave his first orders. "Let go after springs!"

"All lines clear aft, sir."

"Fifteen port!"

"Fifteen port on, sir."

'He then ordered "Slow ahead, port" to swing her stern out, but hardly had he uttered the word when there was a colossal explosion and clouds of steam billowed from the engine room hatch. It was the end of the veteran. Patrician's main engine connexions had burst asunder. Young Goodeve climbed sadly down from the bridge. He was never again to have the opportunity of gaining the "N" that he coveted, but England, which offered vastly greater scope to the scientist, was to widen the experience of the sailor too.'

When in the autumn of 1927 Charles arrived in London with his 1851 Scholarship, he reported to Professor Frederick Donnan, F.R.S.-that distinguished physical chemist who was then head of the Chemistry Department at University College London. Charles had expected to start work immediately but Donnan refused to let him into the Department until he had spent a week 'getting to know London past and present, its museums and art galleries, its theatres—'just walk about and tell me what you've learned this time next week'.

Charles and Donnan and Donnan's sister Jane, who worked as his personal secretary, immediately took to one another. For the next decade Donnan maintained a great interest in Charles's career and as Charles himself used to say, became a foster-father to him.

Charles found he had come to an outstanding chemistry department, which was then one of the leading centres for chemical research in Britain and indeed in the world. It was a school of many parts with scarcely a side of physical chemistry unrepresented. Donnan was a remarkable Head, anxious to make and help young scientists and taking a personal interest in the work and activities of all the staff, fellows, and research students. His attractive personality and good connections with industry, and particularly I.C.I., enabled him to raise adequate funds to run his prestigious Department.

Charles had intended to extend his earlier electrochemical researches, but, with his eyes opened to new possibilities, he followed the advice of Donnan and started to work on new topics which were then full of promise, notably unstable molecules and absorption spectra. This led him into photochemistry and the associated reaction kinetics and ultimately into his work on the physical chemistry of vision.

In 1932 Charles married Janet, the daughter of a Presbyterian minister. She had been born in Ontario, and brought up in southern Saskatchewan. Janet was keen on science and after teaching for a few years in primary school went in 1924 to Manitoba University where she studied chemistry. She was in the chemistry class to which Charles lectured in his closing years at Manitoba and the two of them became friendly. In 1929 Janet graduated top of her year: she was awarded the University Gold Medal and a small travelling scholarship. She thought of using the money to visit and work in the United States. Charles, however, heard about her success and got Professor Donnan to add sufficient funds from his I.C.I. grants to make a year's visit to University College possible. So she came to London and worked on the spectroscopy of chlorine monoxide under Charles's supervision. The arrangement was a success in all ways for she got her Ph.D. in 1932 and that same year married Charles at her parents' home in Goodlands, Manitoba. They returned to London where they settled for good. Janet became a leading member of Charles's research group, and, supported with I.C.I. money, worked on the absorption spectra of ethyl nitrate and nitrite, nitroethane, and methyl methacrylate and its polymer.

Charlas and Janet had two sons, Peter Julian and John Anthony. The older is an expert in computer software, and the younger a business executive.

In 1928 Charles became an assistant lecturer, having proved himself by successfully giving C. W. Bonnicksen's physical chemistry lectures at less than a day's notice when Bonnicksen was unexpectedly called away. Charles was appointed Lecturer in Physical Chemistry in 1930 and Reader in 1937. He was popular with the chemistry students who enjoyed his lectures, enlivened as they were with elegant and stimulating practical demonstrations. His thermodynamics problem classes were equally successful and he got us all to appreciate the value of the subject by putting it cleverly to use. We students admired his skills as dancer and skater, and were impressed with his wild rendering of the Manitoba University war cry: this he was prevailed upon to give at every departmental Christmas party.

Charles developed closer links with industry than was customary at that time. He orientated important parts of his research towards industrial problems and by this means obtained funds for his growing group despite the shortage of D.S.I.R. grants.

Charles left his research students very much on their own, unless they were in real difficulty. Then he would work alongside them at weekends and even at night and thus gave all the encouragement they needed. He expected his students to seek him out when they needed help: they had to, for he was often very difficult to find, as he had so many active interests both outside and inside the College. It was a common complaint that one had to hold discussions with him while walking fast down the long corridors of the Department or while he was running upstairs and into the street to catch a train. But these disadvantages were more than offset by his friendly enthusiasm, great energy and versatility.

During his time at University College Charles became a keen member of the Faraday Society and many of his papers were published in its journal. He became a member of its Council in 1935, and after the War was President from 1950 to 1952. For his researches which are described in the next section he was elected a Fellow of the Royal Society in 1940.

Charles kept up his naval interests through the R.N.V.R. He went to sea in submarines and minesweepers, and served in four battleships and three destroyers. He qualified as a torpedo specialist at Devonport and then specialized on the electrical side.

In 1936 he was promoted to the rank of Lieutenant Commander and began to direct some of his researches towards naval problems. For these he obtained Admiralty finance and as a result became acquainted with Admiralty departments and procedures. He did attachments in H.M.S. Vernon, the mining establishment in Portsmouth, and these led to his being appointed there when war broke out in 1939.

As a result of his naval experience, Charles saw great value in scientific and engineering skills being coupled with experience at sea. It was like the old argument of a chemical engineer's achieving more than a chemist working with an engineer. So he tried hard in 1938 and 1939 to get scientists and engineers specially enlisted into the R.N.V.R. But he had no success. The Admiralty took the view that scientists and engineers were civilians who should work ashore: they did not need experience of problems at sea, for they could get all the advice they needed from regular officers. How wrong they were and how soon Charles proved it were shown by those wartime successes which are described in a later section.

Except for his early electrochemical studies which have already been described, Charles's original scientific work was done during his time at University College between 1927 and 1939. With an expanding group of research students, he began a programme on the absorption spectroscopy of rather unstable molecules. He established the band spectra and the onset of diffuse or continuous absorption which led to dissociation. In those days such work was far more laborious than now, for all measurements had to be made by photographic methods. Yet Charles's measurements have stood the test of time and are accepted in modern texts. Amongst the gaseous molecules he investigated were ClO2, Cl2O, ClO3 (and Cl2O6 liquid), H2S, H2Te, H2Se, BrF3, IF5, CNF, HBr, SO3, HI, C12, CH3, CH3Br, C2H5I, NOCl (and Br2 liquid).

Such studies led to consideration of the nature of the dissociation products, the quantum efficiency and the decomposition mechanism, and it is mainly in regard to mechanism that more modern work has led to changes. The work led Charles to devise neat three-dimensional models representing the potential energies of systems of three atoms, such as 3H, C + 2O and 2Na + Cl. These made it possible to visualize the reaction paths of minimum potential energy and were a great help in teaching.

Interest in the chemical effects of radiation led Charles into a technical photochemical problem—the fading of paints and oxidation of their oil vehicles (chalking). He pioneered a diffuse reflection method for studying the absorption spectra of white pigments such as ZnO, TiO2, PbSO4, PbCO3 and BaSO4 in the wavelength range 500-250 nm, and went on to study the fading of dyes adsorbed on such powders. With 'Chlorazol Sky Blue FF' on Ti02, for example, he showed that there was fading at a rather low quantum efficiency at wavelengths where the dye alone absorbed, but at shorter wavelengths where the TiO2 absorbed the quantum efficiency increased some 200 fold. To avoid fading and chalking in paints, photochemically active oxides are now coated with inactive oxides such as alumina. Charles later showed that increasing temperature greatly increased the bleaching rate and that the presence of moisture was also necessary; the bleaching was also markedly affected by metallic salts, some inhibiting and some enhancing. The work was extended to the decomposition of Sb203 by light and the influence of moisture and various, mainly organic, additions.

In the 1930s relatively little was known about the oxides of chlorine, so Charles developed a continuing programme to measure their properties, despite experimental difficulties and the risks arising from their unstable nature. He established the vapour pressure of chlorine monoxide and its absorption spectrum. He then determined the heats of dissociation of C12O and ClO2 in a calorimeter, in which small quantities of these gases were successively exploded to give temperature rises of about 0.5°C. Chlorine hexoxide was then investigated. It was shown to consist of ClO3 in the gas phase where its absorption spectrum was established; by studies of magnetic susceptibility in the range - 40 to + 10 °C, the solid and liquid hexoxide were shown to exist as Cl206 with no more than 1% by mass of ClO3. The heat of decomposition of ClO3 was determined by streaming it continuously over a red hot platinum filament in a calorimeter. A similar method was used for chlorine heptoxide and its vapour pressure was also measured. Cl203, which had been previously claimed as an oxide, was shown not to exist. Because of the experimental difficulties, little of this work has ever been repeated and the data established by Charles and his students remain almost without exception the best available today.

Charles's investigation on the absorption of sulphur dioxide from the flue gases at the Battersea Power Station led him to an interesting series of researches on the oxidation of sulphurous acid solutions, and on the formation of sulphuric acid mists from water vapour and sulphur trioxide. A centrifugal method of removing such mists from gases was devised and operated successfully in the laboratory, but it was not suitable for industrial application.

Charles developed an interest in colloids as a result of a technical problem on printing inks and the arrival of Professor Herbert Freundlich (the doyen of colloid chemists) and his research group at University College following the rise of Hitler. Freundlich had shown that many colloidal solutions exhibited a decrease in resistance to flow on being stirred, and reverted more or less to that previous resistance on being allowed to stand. In extreme cases solid gels could be made temporarily liquid by stirring. This isothermal, reversible, sol-gel transformation, was named thixotropy by Freundlich and the phenomenon intrigued Charles.

He designed an apparatus-now called the Goodeve thixoviscometer for measuring thixotropy. This consists of a container (for the liquid) which has a conical internal surface and is rotated at constant speeds. A frustrum of a cone is suspended coaxially inside. The fluid between the conical surfaces imparts a moment tending to rotate the inner cone and this moment is measured by the angular displacement of a torsion wire or spring. With this apparatus Charles was able to investigate thixotropic liquids at constant and uniform rates of shear, and he made exhaustive studies of carbon black dispersed in mineral oils—a suitable model for practical printing inks. He went on to develop an 'impulse' theory of viscosity.

According to this, the thixotropic part of the viscosity arises because links between the colloidal particles are stretched by shear until they are broken, reform after renewed contact (brought about by Brownian motion and by the shearing action itself) and are then stretched again. During each stretching process an impulse is passed from a faster moving layer to a slower moving one. Although there is still no fully satisfactory theoretical treatment of thixotropy, Charles's ideas stimulated thought on how a quantitative theory might be developed. His attempt to derive an absolute coefficient of thixotropy proved to be over-optimistic but his qualitative concepts have found a place in later theories of dynamic structure-making and breaking in weakly coagulating dispersions.

The work on photochemistry led to studies of vision in the ultra violet and extreme red and the limiting wavelengths were established. There followed a series of investigations of visual purple which was then known to be present in the rods which are used for vision at low illuminations (i.e. scotopic vision). This work was done in conjunction with Dr R. J. Lythgoe, who was then working for the Medical Research Council in the Department of Physiology and Biochemistry at University College. The absorption spectrum and the bleaching of visual purple were studied at 506 nm: the value of the photosensitivity-the product of extinction coefficient and quantum efficiency-was determined. From this it was inferred that the quantum efficiency was in the neighbourhood of unity and in successive studies it was shown that between 20 and 60°C and down to - 73°C the efficiency was independent of temperature. (A value of 0.66 is now accepted for the quantum efficiency.)

A study of the variation of the photosensitivity of visual purple (with wavelengths 460-59Onm) showed that this followed closely the corresponding spectral variation for scotopic vision, with both maxima occurring at the same wavelength (500 nm). The facts could be explained only by a photochemical theory of scotopic vision. The investigation was then extended to the near ultraviolet and the sensitivity of the eye measured in this region with a number of observers. For one observer with no natural lens (as a result of a traumatic cataract) the scotopic sensitivity at 365 nm was that to be expected from the photosensitivity of visual purple. For the rest, with normal lenses, the ultraviolet sensitivity was smaller by a factor of 10-4. The difference was, in fact, due to the absorbing power of the natural lens, but at that time the lens was thought not to absorb at 365 nm and other explanations were sought. The carrier weight was shown to be about 25 000, more than 10 chromophores being attached to each molecule.

This work was brought to an end by the war and the untimely death of Dr Lythgoe, but it remains a classic research and the principles established still stand over forty years later.

Much of Charles's naval work was vividly and accurately described by Gerald Pawle in his book The secret war (G. G. Harrap and Co. Ltd, London, 1956). Excerpts from this book have therefore been quoted, with kind permission of both author and publisher, in the sections below dealing with Charles's naval exploits.

With the outbreak of war in September 1939 Charles was appointed to work under Captain Denis Boyd at H.M.S. Vernon. By the time he arrived the Germans were beginning to use their magnetic mines with marked success and a team in the Mine Design Department was hard at work on countermeasures. A magnetic mine had in fact been invented by the British in 1917 and then used in small numbers. Thereafter interest languished in Britain and nothing was done either to improve that mine or to develop countermeasures, apart from one or two theoretical studies. During the month of November 200000 tons of shipping were sunk by magnetic mines and the Port of London was all but closed. By the end of the month a mine had been recovered at Shoeburyness and its principle of operation discovered. It was designed to rest on the sea bed and was actuated by the enhanced north-pole-down magnetic field induced beneath a steel vessel by the Earth's magnetism.

The most promising method of sweeping magnetic mines seemed to be one that had been proposed by Professor B. P. Haigh of the Royal Naval College, Greenwich. The idea was to impose on the sea bed a magnetic field which would actuate the mines by means of heavy electric currents passed through electric cables towed astern by minesweepers. As conceived however the sweep would have required unreasonable amounts of electric power. While studying Haigh's ingenious plan, Charles came across a suggestion by a young scientist called Tuck which looked like solving the power problem. Charles combined this with his own idea for electrodes at the ends of the cables passing current into the sea, and finally produced the paper design shown in figure 1.

It can be seen that two sweepers operating about 200 yards apart might be able to sweep a lane with a N pole down field by using a series of pulses of electric current, each pulse sweeping about 10 acres (4 hectares). The arrangement became known as the Double Longitudinal (Double L) sweep. The next technical question was whether the return currents flowing through the sea between the ends of the cables would neutralize the magnetic effects of the currents in the cables. There was a divergence of scientific opinion and an experiment was required. This has been well described by Gerald Pawle (1956):

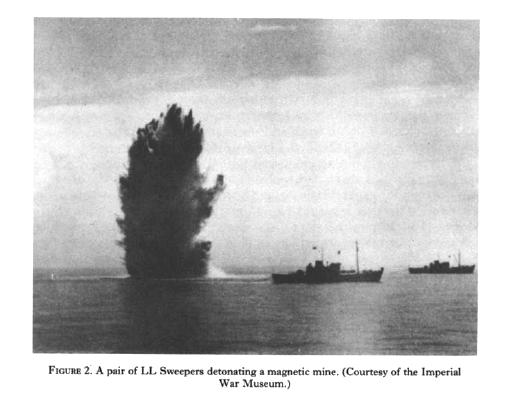

'For the trial they needed a calm stretch of water where they could work undisturbed—and it had to be sea water. Right on the spot in Portsmouth was the ideal place—the Canoe Lake, where small boys sailed their model yachts—but security was the snag. The Canoe Lake was in full view of the public, and overlooked by nearby houses. Any attempt to screen it off would undoubtedly attract attention and it was important that the sailors helping with the trial should not realize what was happening. So Goodeve thought up an ingenious cover-plan. In the deepest of confidence the sailors and police were told that a new secret device for detecting enemy ships was being tried. A large number of models were launched on the waters of the lake, some floating proudly as the schoolboys' yachts, and some mounted on pieces of wood.Thereafter it was a matter of getting the engineering to work. A full scale sea trial was arranged for Boxing Day, 1939. Two tugs were loaded with car batteries and Ford V8 engine-driven generators, to provide current for the cables. The cables were not self-buoyant but were lashed to floating spars and although the trials were considered satisfactory, the day ended with one of the tugs aground with a cable wound round its propeller! A self-buoyant flexible electric cable was clearly required and it had to be capable of withstanding the shock waves from exploding mines. The help of the British Insulated Callendar's Cable Company was enlisted. Stimulated by the infectious enthusiasm and inventiveness of Charles, they achieved partial success in a matter of weeks and the first buoyant cable was delivered on 18 January 1940-the first of 1½ million yards to be manufactured by the end of the war. By February the first magnetic mines had been swept by the Double L. Special wooden minesweepers modelled on Yarmouth trawlers were commissioned and they operated most effectively: 74 mines were swept by March, and nearly 300 by the end of June 1940. The speed with which the enterprise was brought to success owed much to Charles's enormous energy and enthusiasm and his skill in dealing both with the naval personnel concerned with trials and the civilians responsible for the design and manufacture of the cables and the electrical equipment. Two sweepers detonating a magnetic mine are shown in figure 2.'It was a bitterly cold winter day, and ice had to be swept aside before the trial could start. Then the sailors began towing their model ships backward and forward across the lake, watched by an overgrowing crowd of housewives, small boys, and policemen.

'Of all the gathering on the lake-side only Goodeve and two assistants knew what was afoot. They had brought with them a large box. In it was the mechanism of the German magnetic mine which had been brought from its resting-place on the mud-bank at Shoeburyness. This could not be placed on the bed of the lake; the water was too shallow. So they decided to reverse the normal procedure, the Doub le L sweep wires being strung out along the bottom of the lake. The mine itself, hidden in the box, was lifted into one of the rowingboats, and as the sailors hauled their model ships to and fro the boat carrying the mine and three tense observers moved slowly among them.

'When they had been afloat, ostensibly engrossed in the movements of the models, long enough to allay any interest on the part of the spectators, they pulled towards the head of the lake. Goodeve bent over the instruments connected to the mine mechanism. At a signal from the boat the current began flowing through the submerged cables. And,as they paddled slowly back down the lake a spasmodic flickering on the dial in front of him announced the firing of the mechanism of the German mine at all the corners of the sweep. In the freezing cold wind, which whipped up small waves on the grey waters of the lake, Goodeve found himself sweating with excitement. It had worked.

'Making his way through the crowd still staring fascinated at the little wooden models, Goodeve hurried back to Vernon. On his desk lay an envelope marked "Top secret", and he extracted a brief, emphatic memorandum with a Whitehall note-heading:

'"You should discontinue any research on the lines you have indicated in your latest report. It is clear to me that the method you suggest will prove self-cancelling, and cannot work".'

When it became clear that the success of the Double L sweep depended only on detailed improvements to make it more seaworthy, Charles (who had by then been promoted to the rank of Commander) began thinking about protecting ships directly. The Admiralty had already set up a vigorous organization to protect vessels by fitting them with fixed copper cables: these carried an electrical current which induced a N-pole-up magnetic field to counteract the ship's own N-pole-down field. But there were neither cables nor fitting facilities sufficient to cope with the great numbers of'ships that required protection. Warships and the largest merchant ships had priority: something was desperately needed for the rest.

I was working as a Sub-Lieutenant with Charles at that time and well remember discussing with him the French suggestion that ships should have permanent S-pole-down magnetism induced into them by subjecting them to a very strong magnetic field in a wet dock surrounded by an enormous electric coil. The trouble was that the power required and the cost of even one installation would be exceedingly great. Charles saw that the idea of inducing permanent magnetism in a ship was the right one but somehow the current required must be vastly reduced. He then had the idea of passing a horizontal flexible rubber-insulated electric cable up and down a ship's side so as to induce the required permanent magnetism in the ship's plates. It was easy to see that the magnetic field caused by 1-2000 A, flowing only the half thickness of an insulated cable away from a steel plate, would magnetize it. But it was conceivable that as the cable was lowered away from any part and the direction of the induced field changed from vertical towards the horizontal the net permanent magnetic effect might become negligible. Furthermore the remaining permanent magnetism might be quickly shaken out. The scientists were not optimistic. Goodeve however went to the Admiralty and _put forward his ideas, but nothing happened. So the next weekend at his instruction 1 started experiments in H.M.S. Vernon with a number of ship's plates and, when the results looked promising, with Vernon's steel cable-lighter. Again the results were promising and when it became clear that the permanent magnetism induced withstood the vibration of the lighter's engines our excitement was intense. Progressively larger ships were subjected successfully to trials and the method was christened 'Wiping'. Of course Charles realized that the protective permanent magnetism could decay slowly due to engine vibration and the pounding of the sea, but it was obvious that a large ship could be wiped very cheaply by its own crew under expert supervision in a day or less, and a small one in a few hours: also that it would be no great problem to wipe each ship in dock every six months or so. It was duly found that the induced permanent magnetism lasted longer if the ship were first overwiped and then part of induced magnetism removed by wiping with a reversed but lower current.

It remained important to discover whether destroyers and other naval vessels made of D type Admiralty steels could be equally well protected. We were promised two destroyers from the Naval Dockyard for tests, but they were never forthcoming, because the Admiral Superintendent of the Dockyard was more intent on getting damaged destroyers back to sea, than making any available for magnetic trials of uncertain outcome by a relatively unknown Commander R.N.V.R. Charles travelled to the Admiralty for support but found that Rear-Admiral W. Wake-Walker to whom he reported on anti-magnetic measures was unfortunately away. So he risked sending the following signal to the Admiral Superintendent: 'Urgent. Please summon Commander Goodeve and find why he has not yet reported on the results of wiping destroyers'. Before Charles got back by train from London, 1 had received a signal for him from the dockyard instructing him to do the wiping trials forthwith on two named destroyers! The results were very successful.

There was some opposition to the idea of wiping ships that might later be protected by coils, because the wiping might introduce permanent magnetism which would make the design of the coils ultimately required much more complex. In the end however the wiping technique became a useful adjunct to coiling, for it was used to remove excessive permanent longitudinal magnetism sometimes present in a vessel (probably as a result of its heading when under construction) and so simplify the coiling arrangements.

It was realized that wiping was at a disadvantage compared with coiling, because a ship so protected could not adjust to changes in the Earth's magnetic field. It would thus be at risk in the southern hemisphere if the enemy extended the war there with S-pole-down mines. Coiling was therefore reserved for warships and other major vessels that had to go around the world and wiping for smaller vessels that did not range so widely.

Charles next did tests on submarines and these were highly successful. For structural and sea-going reasons, submarines could not be fitted with coils so wiping became the only method of protecting them. They had the advantage of being able to wipe themselves whenever it became necessary by using their own powerful batteries and so could change their polarity if required.

At about this time Charles invented the word 'degaussing' after Karl Friedrich Gauss and it was adopted to cover all methods of protecting ships against magnetic mines. Charles used jokingly to say that he invented the word because it aptly rhymed with 'delousing' and because Gauss's initials were virtually the same as his own.

By April 1940, ten wiping stations were operating in Britain; by June about 1000 ships of all kinds had been wiped and many vessels that took part in the Dunkirk evacuation were so protected. From then on about 10000 ships were wiped or rewiped, or depermed, until the end of the war.

After the war this invention was recognized by the Royal Commission on Awards to Inventors. Charles received an ex gratia award of £7500 which was the largest individual award made in connection with claims for devices designed to combat magnetic mines. This he generously shared with those who had helped him bring the idea to success.

With the success of these counter measures to the magnetic mine, Charles began to wonder what he should do next. Throughout his time in the Vernon he had been making frequent trips to the Admiralty in London, finding out how it worked and making friends wherever he could. His reputation for cutting through red tape and pushing his projects against all opposition, had produced enemies as well as friends. In the Vernon the expression grew up 'to do a Goodeve': that was to do something by hook or by crook and junior officers who felt they were unable to do this or that without more authority or considered they were being asked to do the near impossible, were often told abruptly to 'go and do a Goodeve'.

When the work on wiping was coming to an end, Charles was warned by a friend in the Admiralty that he was likely to be transferred to the staff of a certain Captain R.N. with whom he knew he could not possibly work. He had to act swiftly. As Gerald Pawle wrote:

'Goodeve's one hope was Rear-Admiral Wake-Walker, the pivot round whom all the anti-magnetic-mine measures had centred. At their last meeting Wake-Walker had mentioned a new department which the Admiralty were setting up under Vice-Admiral J. Somerville. [*Later Admiral of the Fleet Sir james Somerville.] Unable to get Wake-Walker on the phone, he took his courage in both hands and rang up Somerville, only to find he had left for Dover; he had been temporarily detached to assist Admiral Ramsey with Operation Dynamo. It was to Dover that Goodeve went that night. . .The existing I.A.A.W. & D. group consisted of four officers concerned with the development and fitting of kite balloons and kites to small ships as a deterent to low level and dive bombing attacks. The group were accommodated in a small office in the Archway Block of the Admiralty. When Charles arrived in London with me as his assistant, this was where we went. Our immediate task was to improvise weapons for use against aircraft. So we made a rapid tour of development establishments concerned with A.A.'Goodeve met Somerville in Ramsey's house above the fortress at Dover, and took to him immediately. . . As they snatched a hasty meal they mulled over ideas for anti-aircraft measures, passive defence, and rocket warfare. The mounting German air offensive against Allied shipping and the desperate shortage of close-range weapons to combat it was a theme to which Somerville returned again and again. He was convinced that the danger was not fully appreciated; divebombing attacks on coastal traffic and long-range assaults by heavy bombers on the Atlantic convoys could strangle Britain's war supplies. Back in the operations room they talked with many interruptions right through the night, Somerville plying the scientist with questions. It was after daybreak when Goodeve walked down the hill to catch the first train for London. In his pocket was a request to the Admiralty scribbled in Somerville's strangely boyish handwriting on a sheet torn from a signal pad. It asked for Goodeve's immediate attachment to I.A.A.W. & D. "Collect a small team and get to work on some of those ideas of yours", were Somerville's parting words. "You'll have a free hand, but 1 want results, and 1 want them soon".'. . .

'Somerville's little department had as its immediate parent the Admiralty Signal Division (D.S.D.), but Goodeve soon found that D.S.D.'s control over its new and puzzling offspring was purely nominal. So far, few of D.S.D.'s officers had been able to fathom precisely what the Inspector of Anti-aircraft Weapons and Devices was meant to do; I.A.A.W. & D. were left in splendid and satisfactory isolation.

'Goodeve was in no doubt about his own immediate task. The Navy was desperately short of close-range weapons, and in this high summer of 1940 many merchant ships faced the long hours of daylight with a single machine-gun as their sole armament. The ships had no means of detecting an approaching 'plane, and attacks were often over in a flash, the German fighter-bombers swooping out of low cloud to spray the unprotected bridges with cannon fire.

'As a first step Goodeve realized that a close study of enemy tactics must be made. And orthodox ideas of naval weapons were of little use; there was no time and not enough raw material to produce elaborately finished breech mechanisms, gun-mountings, and barrels, quite apart from the ammunition problem. If the lifeline was to be held, and the morale of the merchant seamen kept high, the ships must be quickly fitted with new devices altogether for striking at their attackers.'

By the middle of June a programme of research was submitted to Admiral Somerville: it included the following principal subjects:

Information on enemy tactics and material A.A.But almost immediately after agreeing to this, Somerville was ordered to his famous mission at Oran. He called Charles into his room one morning, told him he was off to sea and then added: 'If you ever see me in the Admiralty again, Goodeve, I reckon I'll be a damned failure! You needn't worry. Admiral Fraser's very interested in what you are doing, and he'll see no one shuts down the department'.

Wire devices and rockets.

Passive defence including armour and explosive research.

Devices for the detection of aircraft.

To implement the agreed programme Charles considered he required R.N.V.R. officers who had technical or engineering skills from their civilian careers. With the help of Admiral Potter and Mr Mountain in the Admiralty, promising officers were found from those who had volunteered for Naval Service and were training at King Alfred. Other recruits were tracked down in the universities, the professions and in industrial firms. Almost all were Special Branch—distinguished by a band of green cloth between the gold 'rings'. In most cases their naval training was cut short by the urgency of I.A.A.W. & D.'s work. Very soon Charles had two more officers to help him, Neville Shute Norway (engineer and author) and Edward Terrell (barrister) who later became heads of sections: they were followed by many others who were recruited as the needs increased.

With the departure of Admiral Somerville the future of Charles's group was hotly debated in the Admiralty and several attempts were made to 'shoot it down', instigated by Departments which did not like competition with their own activities.

At one time the draft of a paper which D.T.S.D. (the Department of Training and Staff Duties) intended to raise with D.N.O. (the Department of Naval Ordnance) fell into Charles's hands. It proposed that his group be divided between them! As a result of slow and careful discussions Charles persuaded D. T. S. D. that there was little in the group that concerned him and it ought mainly to go to D.N.O. D.N.O. was similarly persuaded that there was little advantage in the group to him and that it ought to go to D.S.R. Since Charles already knew the D.S.R. had no wish to take him over, the situation was safe. In addition to these arguments, no Department could quite see where certain of the group's new projects should go and they were ultimately persuaded that any change would jeopardize their progress.

Early in December 1940 Captain G. O. C. Davies, R.N., was made Director. He was a remarkable officer who had served on the Ordnance Board and later been associated with rocket development: he was hard working, diplomatic and imaginative; he had a great sense of humour and a winning manner; Charles was lucky indeed so suitable an R.N. had been put in charge of his unorthodox group. By mid 1941, the new Department was proving itself, and it had become clear that its work was going to spread rapidly into all kinds of naval developments which fell outside the traditional work of the regular Departments. This spread was looked upon with favour by the Third Sea Lord (the Controller) and the group was renamed the Department of Miscellaneous Weapon Development. The new title was not euphonious but it gave Charles free rein to use his inventive skills and those of his staff: their field for preliminary investigation became virtually unlimited.

At that time in the Admiralty the development and design departments considered that they had exclusive rights in regard to the weapons for which they were responsible. With D.M.W.D.'s wider terms of reference, it became obvious that these rights would frequently be infringed. As a result many paper battles had to be fought and many enraged Directors of Departments had to be assuaged. Luckily Captain Davies was adept at smoothing ruffled feathers and apologizing for the mistakes in procedure, not always unintentional, made by his R.N.V.R. staff. He and Charles became expert in operating the Admiralty docket system. Dockets proposing work on some new device had to be circulated to the staff and production departments likely to be interested. In drafting an original proposal D.M.W.D. officers were advised to suggest wherever possible that a new idea had emanated in some way from an orthodox department rather than from D.M.W.D. If a proposal collected critical minutes from the first departments to which it was circulated, it was likely to collect similar minutes from the rest and the proposal would surely die. It was therefore desirable to get the docket back after the first few minutes had been written and if these were unsatisfactory to destroy the paper and start a new one with a more promising route through the Admiralty. Two or three favourable minutes at the start would often ensure that everyone thereafter wrote 'Concur'.

During the next two years a great number of developments and investigations were undertaken. Charles and Davies together generated enormous enthusiasm. Hard work was enlivened by friendly humour and daily tales of successful and unsuccessful battles with the system. Everyone worked to the limits of his authority; one R.N.V.R. ring was said to be worth two of any other kind, and all knew that if the worst came to the worst they would be 'baled out' by Davies and Charles.

Many of the developments originated from the junior officers, some originated from outside, and some again from Charles himself. But every single one was examined by Charles and generally improved by his inventive and critical suggestions. The two most important inventions of that period were plastic armour invented by Terrell (then a Lieutenant) and the Hedgehog ahead-thrown anti-submarine weapon which was masterminded by Charles. Another vital task which Charles undertook was to get the Oerlikon A.A. gun into production. There were important lessons to be learned about the inadequacies of Naval and Admiralty procedures from all those developments.

The story of the Oerlikon gun factory is an interesting one as it showed Charles's ability to handle a problem which was quite unrelated to the technical problems with which he had so far been concerned. This gun was desperately needed for the A.A. protection of both warships and merchant ships. It was being manufactured by the Swiss who were making them for the Germans and had produced some for Britain during the early days of the war. But with the fall of France and Italy entering the war there was no chance of getting more guns from there.

Although an agreement had been reached to make the Oerlikon under licence in England, progress had not got beyond the planning stage. A factory had been earmarked at Brighton, but when France fell this was considered too vulnerable, and a new prospective site was suggested at Bangor, in North Wales. A well-known civilian engineering firm in the Midlands had been chosen to make the gun, but they had many other projects on their hands, and there the matter rested. June and July passed, and still no manager for Oerlikon production was appointed.

Goodeve was asked to look into the Oerlikon situation. He talked things over with Stewart Mitchell,[*Later Sir Stewart Mitchell] who had previously been Inspector of Naval Ordnance Contracts at the Oerlikon factory in Zurich. Then they both went to Bath to confer with the Admiralty department officially responsible for the gun's production. From here the story is well told by Gerald Pawle:

'They were told that everything was going according to plan. Interference from "outside" would only slow up the project. The was no special urgency in building a factory, because they had no machine tools, and if any help was needed it could only come from someone with gun-production experience. The meeting broke up on the complacent note that the first Oerlikon might be produced from the British factory in two years' time.The last major problem arose because the machinery needed to bore the gun barrels failed to arrive, threatening a delay of three or four months. Searching for some way out, Goodeve suddently thought of William Dennis Kendall who at his works at Grantham was turning out barrels of a gun very similar to the Oerlikon-the 20-mm Hispano which he was making for the R.A.F. Kendall proved a willing ally, despite the fact that his was an M.A.P. factory, and as soon as the predicament of the Oerlikon factory was explained to him, he made an immediate offer of fifty barrels within a month, to be followed by a second fifty. This tided the naval factory over its crisis.'Soon after he got back to London Goodeve was summoned to see the First Sea Lord, Admiral of the Fleet Sir Dudley Pound . . . Goodeve explained the incongruous situation—there was no factory because there were no machine tools, and yet the Admiralty were not entitled to any machine tools unless they had a factory to put them in! Pound Listened intently. "You have my full backing in anything you can do to get the guns", he said. With this carte blanche Goodeve went ahead. On the way back from a profitless three-day search for a suitable building in the Midlands he noticed from the train some new railway repair sheds at Ruislip. These looked ideal for conversion to the factory they needed, but there seemed little chance of persuading the Ministry of Supply to hand them over to the Admiralty unless he resorted to bluff.

'He took his courage in his hands. When he appeared before the Chairman of the Allocation Board next morning to state his claim he explained the vital need for the Oerlikon, and then announced boldly, that he had 250 machine tools but no factory to put them in. A few moments later he walked out of the meeting with a requisition notice for the Ruislip sheds in his pocket and went to see Sir Percy Mills the Controller-General of Machine Tools. After waving the requisition note in front of him, Goodeve got an initial allocation of tools within a week. At long last the Oerlikon project seemed to be moving ahead.

'The next step was to persuade D.A.S. and the firm they had chosen to make the gun that the Ruislip sheds now in their hands provided a sensible alternative to a non-existent factory at Bangor. In addition, a target time for production had to be fixed. This produced a battle royal round the Controller's conference table, with Admiral Fraser acting as a firm referee.

'Goodeve's opponents, prophesying prompt destruction of any project at Ruislip by enemy bombing, lost their case for Bangor; the saving in time by using a ready-made building justified the risk ol bomb damage. Argument then switched to the target date for producing the first gun.

'Having gone into the design of the Oerlikon with Mitchell and studied the production problems as closely as he could, Goodeve was sure the first gun could be finished in six months. . . . At tea after the meeting Goodeve backed his opinion with two wagers. To the manufacturer he offered a bottle of brandy if a bomb fell on Ruislip before the first Oerlikon was finished; to the Director of Naval Ordnance he promised another if the first Oerlikon took longer than six months.

'For a short time there was furious activity. The makers of the gun rushed their architects to Ruislip; London Passenger Transport Board moved their Underground railway coaches out of the sheds; and machine tools began to arrive. . . . Goodeve, who had been dealing with personnel problems, ran up against a snag which threatened to slow up production. There were not enough executives to supervise the work at Ruislip, and by the end of October things looked black. Only thirty of the machine tools had been wired up; the architects and builders were weeks behind schedule, and Goodeve often found himself in sole control at the sheds issuing and approving plans because the manufacturers had no one on the spot to take decisions.

'The firm under contract to build the gun had many other projects on their hands for the Services. . . . They took the attitude that they could do nothing to hasten the job, and Goodeve, worried at the lack of drive which left the existing resources of the factory idle, was finally forced to report to Admiral Fraser. The Admiral descended on Ruislip. . . . His visit galvanized the manufacturers. Within a few months the factory was a hive of industry, and Goodeve, who was spending half his time there and half at the Admiralty directing the labours of his research team, began to feel that his somewhat thankless task with the gun was almost at an end. Before he could return to his own department, however, he was involved in two memorable incidents.

'When work on the gun began at Ruislip, Russia was still an ally of Germany, and Communist agents lost no time in stirring up trouble in the factory. With Ruislip's not getting under way until the end of 1940, the Oerlikon management could not pick and choose their workers; they had to take on a very mixed bag, among them a number of undesirables already dismissed from other factories. Here was fertile ground for Communist propaganda.

'Agents were infiltrated into key positions and for some time the shop stewards were able to discover in advance the gist of many decisions taken by the management. This tactic won the Communists much support as champions of their workmates. . . . The spirit in the factory worried Goodeve. With the country fighting for survival, here were British workmen doing their level best to sabotage the war effort. To bring home to the bulk of the men the importance of the Oerlikon he got permission for a sailor who had fired the gun in action to come down to Ruislip and give a talk one day during the lunch break. The ideal ambassador arrived from one of the home ports—a great burly Able Seaman who gave a vivid description of the fighting at Narvik, where he had manned an Oerlikon mounted on a raiIway truck, and his gun had been heavily engaged against the German dive-bombers. In his breezy, natural way he was the best possible advocate for the new gun, and he got a tremendous reception, which made the sequel to his visit all the more bizarre. On the following morning the shop stewards demanded to see the management. "We realize now how important this gun is", said their spokesman, "and we think it's a damned disgrace what you're paying us". With that he thrust forward a claim for higher wages for the whole factory staff, and threatened an immediate strike if this was not granted.

'With the shortage of manpower it was not easy to deal with indiscipline, and permission to dismiss workers had to be secured from the Ministry of Labour. "You'll have to fire them", Goodeve told the works manager, and, to his relief, the permit was given. Two hours after the trouble-makers were sacked the inevitable deputation of shop stewards arrived with an ultimatum. "Either the men are reinstated or we call out the whole works", they said.

'Goodeve walked down into the factory and, calling the men round him, he said to the ringleaders hanging on the fringe of the crowd: "Tell your brother-workmen what your complaints are".

'The malcontents had their say, and then Goodeve's turn came. He told the men of the ultimatum which had followed the Able Seaman's talk; he told them about the leakage from confidential meetings, and how in every case the agitators had taken the credit for decisions already made by the management. He then suspended work for the day: "Make up your minds by nine o'clock tomorrow if you want to go on working here", he said bluntly . . .

'Next day every man in the Oerlikon factory, with the exception of the three who had been dismissed, was back at his job. The workers held a fresh election of shop stewards, and from that time there was no trouble.'

With the teething troubles of the Oerlikon now at an end, Goodeve was free to grapple once more with D.M.W.D.'s normal work. He continued to follow reports of the Oerlikon's progress with keen interest. No bomb ever dropped on Ruislip, and although he lost one of his wagered bottles of brandy his estimate was not far wide of the mark. The first gun was finished and successfully tested in seven months. Within a year Ruislip was turning out 750 Oerlikons every month, and by the autumn of 1942 this output had risen to 1000. Shadow factories in the West of England were turning out half as many again. Vast numbers were later produced in the United States.

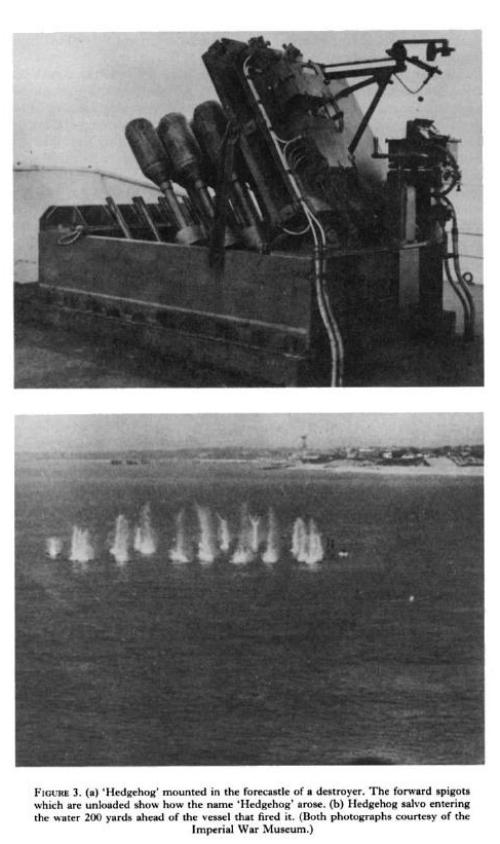

Towards the end of his time in Vernon, Charles had heard of attempts being made at H.M.S. Osprey to develop a weapon to throw antisubmarine charges ahead of a destroyer or corvette. Such an aheadthrown weapon could in principle be far deadlier than existing depth charges, which were dropped astern and gave a submarine too much time to take avoiding action during an attack. After D.M.W.D. had been formed with its wider terms of reference, Charles returned to this problem which had assumed much greater importance because of the enormous success of the German Atlantic submarine offensive. In November 1940 1 was investigating the possibility to using a type of spigot mortar developed for the army by Major Mills Jefferis of M.D.I. at Whitchurch, Bucks., for the purpose of propelling wire devices against aircraft attacking ships. I suggested to Charles that he should consider this mortar for his anti-submarine projectiles. He was quick to take up the idea and soon envisaged a weapon firing a pattern of relatively small contact changes from an array of spigots mounted in the forecastle of an escort. In the final design there were 24 projectiles in the pattern, each with a charge of 31 lb of explosive: they landed in a 130 ft diameter circle 215 yards ahead of the firing vessel. The weapon is illustrated in figure 3.

The most attractive features of the proposal were lightness of the mounting, the sea worthiness of the loaded round and the possibility of firing the pattern of projectiles in a ripple, so that no strengthening of the forecastle would be required. The preliminary design of the mounting was drawn up by Major Jefferis, whereas the design of the, projectile and the study of its underwater trajectory were undertaken by a group in D.M.W.D. led personally by Charles. Two designs for the fuse, which became armed as the projectile passed through the water and fired on contact, were developed simultaneously. The successful one was mainly the work of Lieutenant Commander H. D. Lucas on the staff of the Chief Superintendent of Armament Design, assisted by D.M.W.D. From here the story is told by Gerald Pawle:

'The speed in which a new weapon could be put into service, depended, however, on the priority allocated to its full-scale production, and here Goodeve knew he would have to secure influential backing. No matter how much he and his department believed in the new weapon, they had no say in the matter of priorities; these were decided on a much higher joint-Service level.By May 1941 the Hedgehog mounted in the destroyer H. M. S. Westcott was ready for sea trials against a submerged wreck in Liverpool Bay. The weapon functioned perfectly. The Admiralty went all out for the Hedgehog and before the end of 1941 it was being fitted into our escorts. Later American escorts were similarly armed and by the end of the war the weapon had accounted for some fifty enemy submarines.'He and Captain Davies were still considering ways and means of boosting the Hedgehog's claims when they learnt that the Prime Minister was to be present at trials of a new type of anti-tank bomb which Jefferis was staging in a chalk quarry not far from Chequers. If they could capture Mr Churchill's interest in their own new weapon the battle was as good as won, and as Chequers was quite close to M.D.I. at Whitchurch this seemed the ideal opportunity. The trial was taking place at ten o'clock one Sunday morning, and Lord Cherwell readily agreed to suggest to the Prime Minister that he should drive over to Whitchurch after watching the anti-tank demonstration. When the day came, however, Davies and Goodeve, deciding to leave nothing to chance, set off for the scene of the first trial. The area near the chalk pits swarmed with military police checking the identity of every visitor, but although neither of the interlopers from D.M.W.D. had passes with them, Davies waved some entirely irrelevant documents out of the car window and they were allowed through the cordon.

'On a grassy slope in front of the targets they found a distinguished gathering of Service leaders and civilians, and jefferis put on a spectacular show for them. . . . After a while the Prime Minister looked at his watch. 'Time for lunch', he remarked, and began to walk back up the slope, the onlookers forming a line along which he passed. Taking a strategic position at the far end of the line, Goodeve looked round for Davies to support him, but he was nowhere to be seen, so when Lord Cherwell introduced the R.N.V.R. officer to the Prime Minister, Goodeve hurriedly brought up the subject of the Hedgehog on his own.

'Mr Churchill listened intently, and then, looking again at his watch, he said: "I'm sorry, but I haven't time to come and see this weapon now. We are late already".

'He turned away, and was about to get into his car when his daughter, who had just walked up to the group, firmly grasped his arm.

'"We must see Captain Davies's bomb-thrower, Daddy", she pleaded, "of course there's time". Davies, with his winning manner, had not been idle!

'Smiling ruefully, Mr Churchill gave in, and the procession of cars shot away to Whitchurch. Watching the Hedgehog give a highly impressive account of itself, the Prime Minister soon forgot all about his lunch.

'The mortar was set to fire twenty-four rounds, two at a time in quick succession, until all the projectiles were in the air at once. Climbing the blue sky, they formed a strangely graceful pattern and as they reached their zenith they turned lazily over, before starting their swift dive to earth. Then came the bangs of the discharges as they landed round the target-the shape of a submarine outlined on the ground with white tapes.

'The Prime Minister asked for a second salvo to be fired . . . then a third. Here at last, it seemed, was the instrument which could turn the tide of the U-boat war, and Goodeve did not have long to wait for repercussions of this successful demonstration.

'The following morning the First Sea Lord sent for him.

"This anti-submarine gun of yours . . . how soon can you arrange a trial for me?" asked Admiral Pound. And straightway he promised all possible assistance in getting the Hedgehog into operational use.

'This new and influential support came at a timely moment. Although there had been no serious setbacks in producing the prototype, Goodeve knew that in certain quarters there was keen resentment at the intervention of his little department in a sphere outside its normal field of operations.

'This opposition was expressed in constant sniping at the Hedgehog for shortcomings which had no foundation in fact. Again and again D.M.W.D.'s development officers were obliged to stage extra trials or waste time on elaborate calculations on paper in order to refute criticism for which there was no real justification. The reason for this became clearer when a man in a responsible position in another department arrived one morning and asked to see Goodeve. Point-blank a request was made that D.M.W.D. should abandon work on the new weapon altogether. Goodeve's visitor said bluntly that he wanted a clear field for the development of one of the competing anti-submarine weapons. The future of his own establishment depended on getting their own A.S. weapon into service, whereas Goodeve had no need to enhance his own reputation. Clearly, added his caller, the only honourable course of D.M.W.D. was to cease all work on the Hedgehog forthwith!

'Happily the Hedgehog had now progressed far enough for its merits to be known to a wide circle of naval experts. No amount of pressure from any vested interest could stop production, and after the Whitchurch demonstration Goodeve was in a much stronger position to deal with departmental rivalry.'

Following his outstanding successes in weapon development, Charles was awarded an O.B.E. Then in October 1942 the Third Sea Lord (the Controller) Vice-Admiral Wake-Walker,[* Later Admiral Sir William Wake-Walker] had him appointed Assistant (later Deputy) Controller Research and Development. This was a new civilian appointment in which Charles wielded the powers of the Controller in relation to Research and Development. He had regretfully to relinquish his naval rank but he kept his membership of the Senior United Service Club in Pall Mall and so ensured he did not lose the opportunities he had before of meeting senior naval officers informally and of keeping in touch with their views.

With this move Charles's authority and influence were greatly increased, for the whole strategy of Research and Development for the Navy now came under his direction and he could give Board approval for Research and Development expenditure. His place in relation to Admiralty and Government organization is shown in figure 4 [not reproduced here]. He was a full member of the Deputy Chiefs of Staff Committee and had access to papers up to Cabinet level.

The Department of Miscellaneous Weapon Development that Charles had built up continued strongly and so did his concern for it. Its work changed with naval needs: it had begun with anti-aircraft developments, it proceeded to anti-submarine and ended with beach assault. From this Department Charles drew the officers he needed when he formed the Department of Admiralty Research and Development (India) with headquarters in New Delhi. Its purpose was to identify and study technical problems arising in the Far East.

The new office that Charles set up was very small compared with the large Department of about 50 officers and 10 civilians he had just left. His new group consisted merely of himself, assisted by Lt Comdr Sidney Brookfield, R.N.V.R., whom he took from D.M.W.D., a personal secretary and a typist.

Charles's first action was to draw up a series of large wall charts outlining the entire research and development activities of the Navy, and whenever relevant of the other two services. The work of the Americans and other allies was included as far as possible. Progress on each project was entered into the charts so he could tell at a glance whether developments were likely to meet staff requirements in time, what priorities should be assigned or changed and where to turn for any expertise he might need. His priorities were a function of the strength of the staff requirement multiplied by the technical promise of early achievement. A stream of information flowed naturally into his office and whatever else was required was found out by Brookfield. Charles influenced all kinds of technical decisions and established priorities by his minutes in dockets, by his discussions with all concerned and by attending vital meetings. Throughout this period Brookfield was impressed by Charles's intellectual honesty, his scrupulous care to acknowledge the source of any idea he might take up and his desire for criticism that might improve any of his proposals.

Charles worked in very close cooperation with the Director of Scientific Research, Dr (later Sir) Charles Wright and gave strong support to Professor Patrick Blackett's[* Later Baron Blackett of Chelsea] Operational Research Group (D. N. O. R.). He worked hard to get Admiralty divisions and departments to share information and strove successfully to break the tradition of exclusive departmental rights to particular kinds of expertise or work a tradition which he had found such a hindrance to new developments when he was creating D.M.W.D.

Inevitably Charles had to cross swords with many influential people

such as Cherwell, Beaverbrook and Mountbatten, but he managed to do

so with very little rancour. He fought as hard against umpromising

ideas as he did for good ones, for he was unwilling to waste limited

resources. He opposed the rocket-assisted bomb designed to penetrate

the heavily protected submarine pens on the French coast: he contended

a satisfactory fuse could not be designed in the time available, and

he was proved right. Although the bombs penetrated the pens they

failed to explode. He was an unrelenting critic of Geoffrey Pyke's

project for building a giant unsinkable aircraft carrier out of ice

strengthened with wood-pulp (termed Pykrete). This had been 'sold'

at the highest levels as a means of providing air cover for a landing

on the French coast. Many

parties were involved and Charles was unable to get the project stopped

although in due course it was abandoned. His letter to The Times

of 7 April 1951 not only sums up the story but reveals his sense

of humour as well:

'This idea, the code name of which was HABAKKUK, would have gone the way

of most of its type, if for no other reason than the fact that ice was

about one hundred times weaker than that required simply to prevent the

break-up of such a structure in the Atlantic swell. Unfortunately, it was

found that the strength could be increased twenty times by incorporating

in the water, before it was frozen, a high concentration of the wood pulp

that is used for making newsprint. This material became known as Pykrete

and in addition to its strength had the amusing and spectacular properties

described by Lord Mountbatten. The tragedy is that these demonstrations

sold what was patently an absurd scheme at a very high level and resulted

in the diversion of some millions of man-hours of allied effort before the

scheme was quietly allowed to die by our American friends. Serious though

this loss was, our language became the richer. For the remainder of the

war the "micro-habakkuk" became the measure of unsoundness of certain

inventions, the "micro-" being introduced to avoid decimals.

'Sir—Readers of The Times of 29 March vlll have been amused

by Lord Mountbatten's story of Pykrete, but they may not

know that this story, like many comedies, had a serious side.

The stimulus of the war brought out the inventive genius of our race with

full force. Not unnaturally, some of the ideas put forward lacked

the elements of soundness desirable before our scarce man-power

should have been dlverted to thcir development. One such

idea was to build an aircraft-carrier out of ice, big enough to

take a large part of the Royal

Air Force down to an unprotected part of the French coast to cover a

first landing on the Continent. Its size was to be five to ten million

tons and of a draught of about 125 ft. It was to be externally insulated

and fitted with a refrigerating plant equal in power to the Battersea

power station, and also would be self-propelled.

Towards the end of the war Charles was instrumental in arranging with the

D.S.I.R. for the formation of the Royal Naval Scientific Service and in

selecting its first Director, Sir Frederick Brundrett. For some years

after the war (1947-50) he tried to get the Admiralty to accept young

scientists and engineers into the R.N.V.R., just as he had tried in 1939.

This time, however, he had all the wartime experience of D.M.W.D. and

other establishments, to support his argument. But to his disappointment

he saw the Navy revert to the policy it had adopted between the two wars

with such unsatisfactory results.

At the conclusion of the war in recognition of his great contributions to the allied effort at sea, Charles was created a Knight Bachelor (1946) and awarded the U.S. Medal of Freedom with Silver Palm.

When the war came to an end Charles was invited at the suggestion of Sir Andrew McCance, F. R. S., to become Director of the British Iron and Steel Research Association. This was to be financed by the steel industry and the Department of Scientific and Industrial Research (D.S.I.R.) through the British Iron and Steel Federation (B.1.S.F.). Charles inherited an embryo organization called the Iron and Steel Industrial Research Council (I.S.I.R.C.). It had a staff of about ten technical people led by Mr E. C. Evans, a fuel engineer. Investigations had been made through various committees which were either joint with industry or with the Iron and Steel Institute (I.S.l., a Scientific Society since incorporated into the Metals Society).

The Council set up to manage B.1.S.R.A. consisted of twenty one members approved by the B.1.S.F. nine approved by the I.S.I. and one by the D.S.I.R. Plant makers were represented on the Council in addition to leading iron and steel producers.

Charles determined to build up a research association worthy of an industry which was then producing about 12 million tons of steel per annum with a turnover of about million pounds. He had one great advantage over other research associations in that his finance came through a single body, the Federation, so he did not have to seek funds from a large number of separate companies. But he had very substantial difficulties to overcome. The steel industry had not been forward looking as regards innovation, the larger companies had their own research organizations and some were suspicious of competition and new ideas arising from the new central organization. In this respect the situation was similar to the one Charles had faced with D.M.W.D. and the established Admiralty departments during the war. The general idea was that B.1.S.R.A. would not invade those areas in which companies had developed exclusive know-how on which their success depended. Instead B.1.S.R.A. would concentrate on problems which were common to most companies and on which they were willing to pool their expertise. It also became apparent that the B.1.S.F.'s idea of having a Research Association to grace the industry and make use of available D.S.I.R. funds (initially from the D.S.I.R. added to from the industry) did not encompass the large and aggressive organization that Charles envisaged. But Charles held the title of Director of Research for the B.1.S.F. as well as Director of B.1.S.R.A., so he had direct access to the highest Councils of the Federation and gradually he got his way.

Charles saw the work of a research association in the terms of science and technology and in relation to the activities of universities and industrial laboratories as illustrated in figure 5, which is taken from his 1962 paper in Steel and coal. He regarded B.I.S.R.A. as complementary to the R. & D. groups within the industry and not in competition with them. The organization that he ultimately established took the form shown in figure 6. The work was conducted by five Divisions and three Departments, the Heads of these being directly responsible to him. The programmes of the Divisions were controlled by five corresponding panels consisting of senior managers or technical men from the industry. Detailed work was controlled by more specialized Committees responsible to the appropriate Panel and again made up of experts from industry and serviced by B.1.S.R.A. staff. The work was carried out either in B.1.S.R.A. laboratories or in works according to the project involved and its state of development.

The Departments concentrated on longer-term, more fundamental work and strove to build up the basic sciences underlying iron and steel production. In the main they controlled their own programmes but they devised them in the light of the needs of the Divisions and in order to get their annual budgets accepted they had to demonstrate the relevance of their work, and had indeed to get part of their funds voted to them by the Divisions. It was perhaps a weakness of this organization that it lacked its own cost accountant so that its assessments of the likely financial gains that would accrue to the industry if a project were successful tended to be amateurish and unconvincing. When it came to budgeting, project worth was assessed in a rough and ready way by Charles's 'p × n' formula, where p was the probability of success and n the need for a solution. In due course this was amended to p × n / t, where t was the likely time required to complete the project. Despite plenty of special pleading by Heads, it was generally accepted that the formula was sensible and worked well and fairly.